WIPtrac

WIPtrac is a Work In Process (WIP) factory floor control system / Manufacturing Execution System (MES) targeted towards high tech manufacturing environments such as Semiconductor fabs, MEMS fabs, semiconductor assembly backend and research & development environments with:

- Integrated SPC Quality, Engineering Data Collection

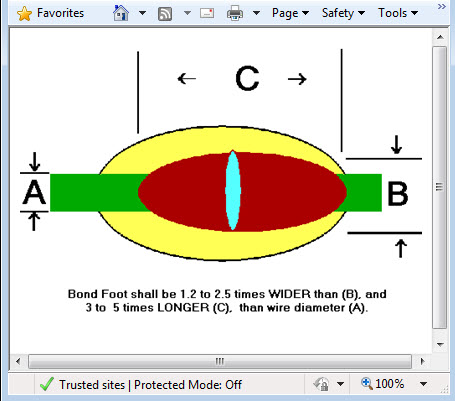

- On-line Manufacturing Instructions Documents and Drawings

- Equipment Tracking, History and Preventative Maintenance scheduling

- Point and Click ERP Integration

- Operator Qualification Tracking ...and so much more

WIPtrac runs in Internet Explorer, Firefox, Safari and on your iPad and smart phone. It can be installed behind your factory firewall and can run securely with a VPN across the Internet. All you need is an Internet connection and you can begin to configure your factory today.

Every component of WIPtrac is fully-configurable from inside the onscreen menu structures. No outside programming is required. No in-house software experts are needed. WIPtrac is suitable for both large and small fabs. WIPtrac provides:

- 80% of the Functionality at

- 20% of the Price and is

- 200% easier to Configure and Maintain than any other true MES ERP MRP solution that you can find. Guaranteed.

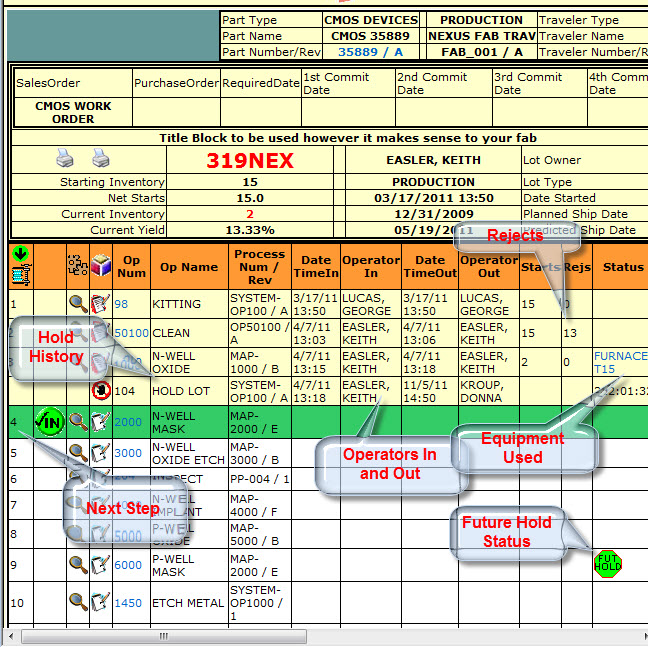

Traveler Capabilities

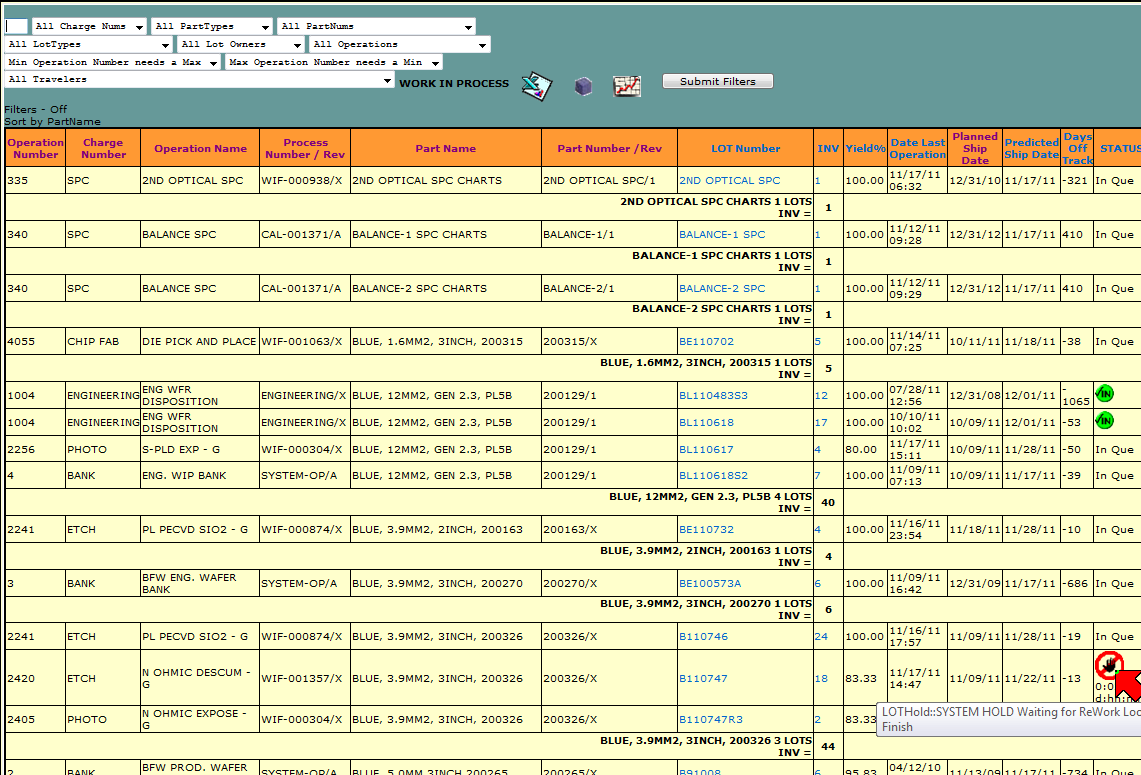

WIPtrac is driven by a traveler/router based factory organizational strategy. Product moves through your factory under the direction of barcoded travelers created by WIPtrac. WIPtrac can run paperless. Flexibility is built in with alternate, optional, and forced out of sequence steps. As Built History is always captured. Traveler revisions and maintenance are under the control of your configuration management team.

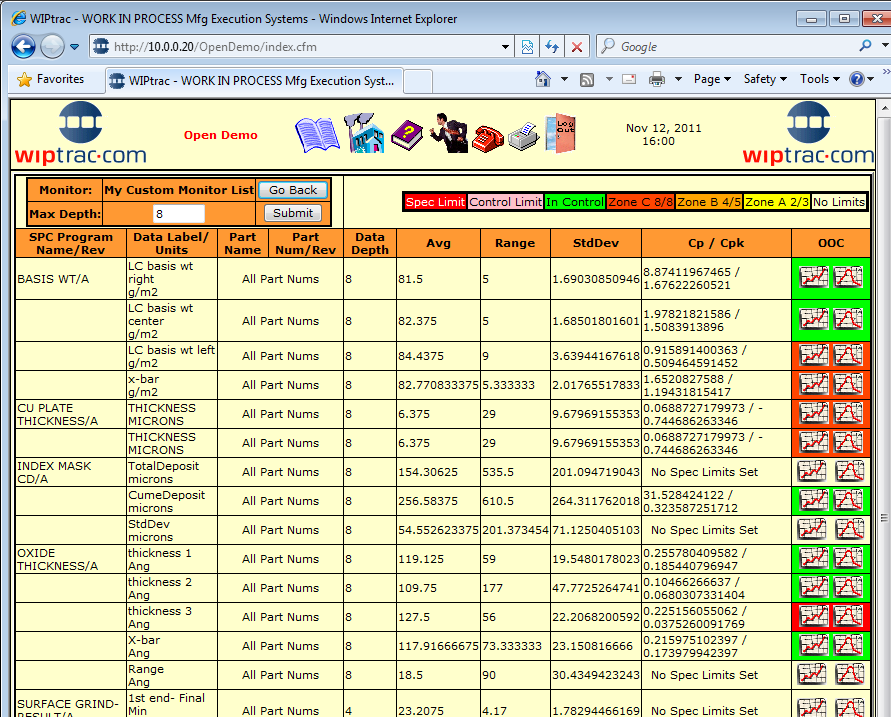

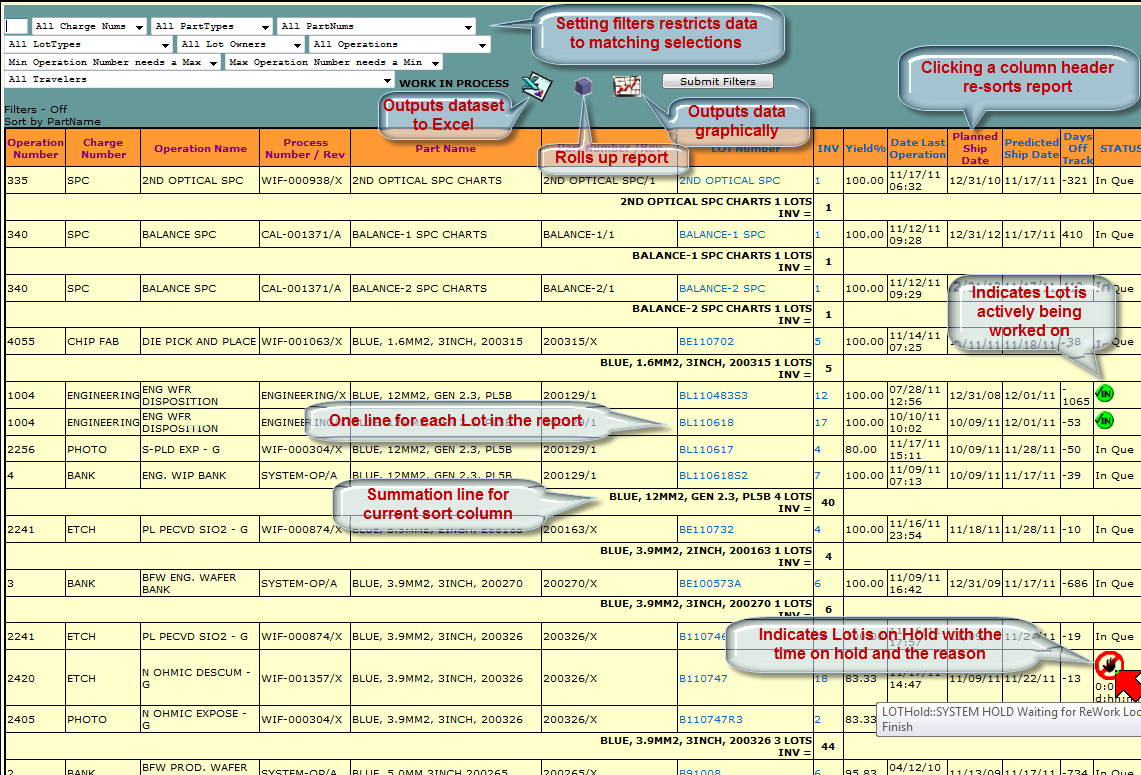

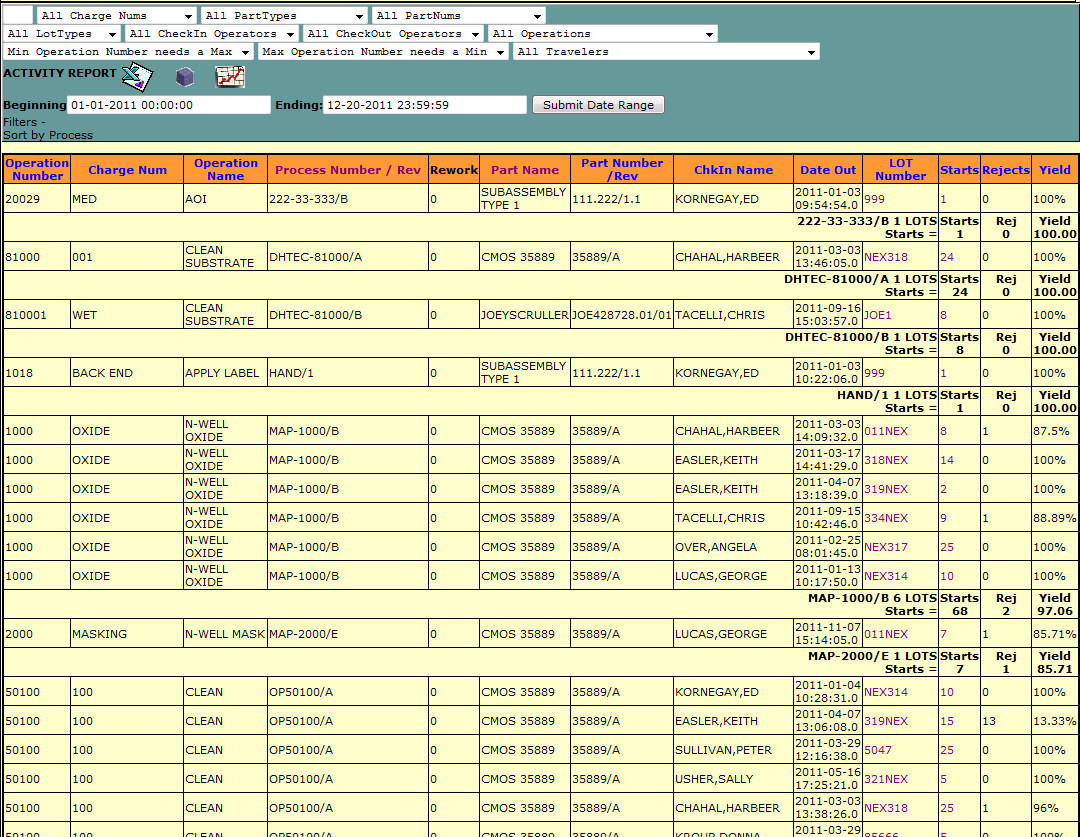

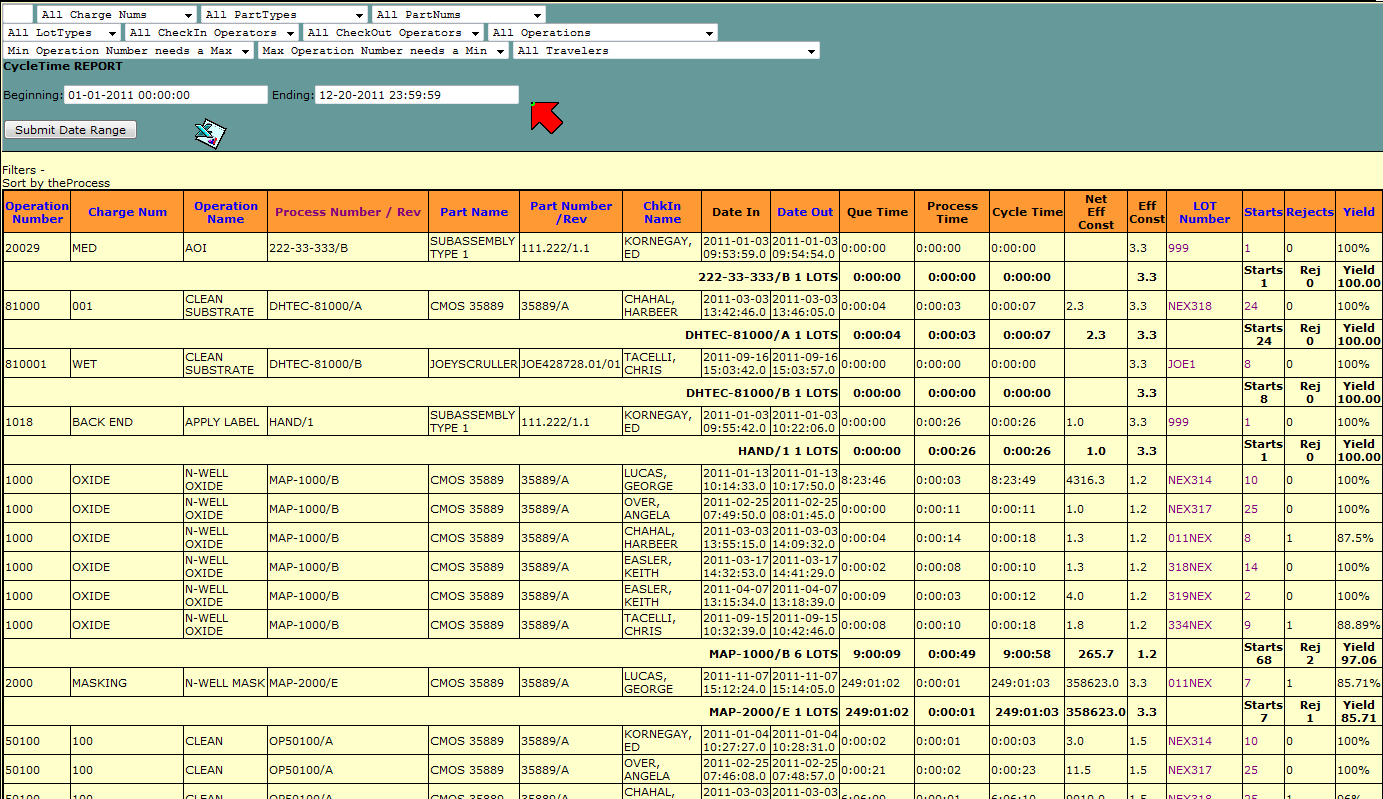

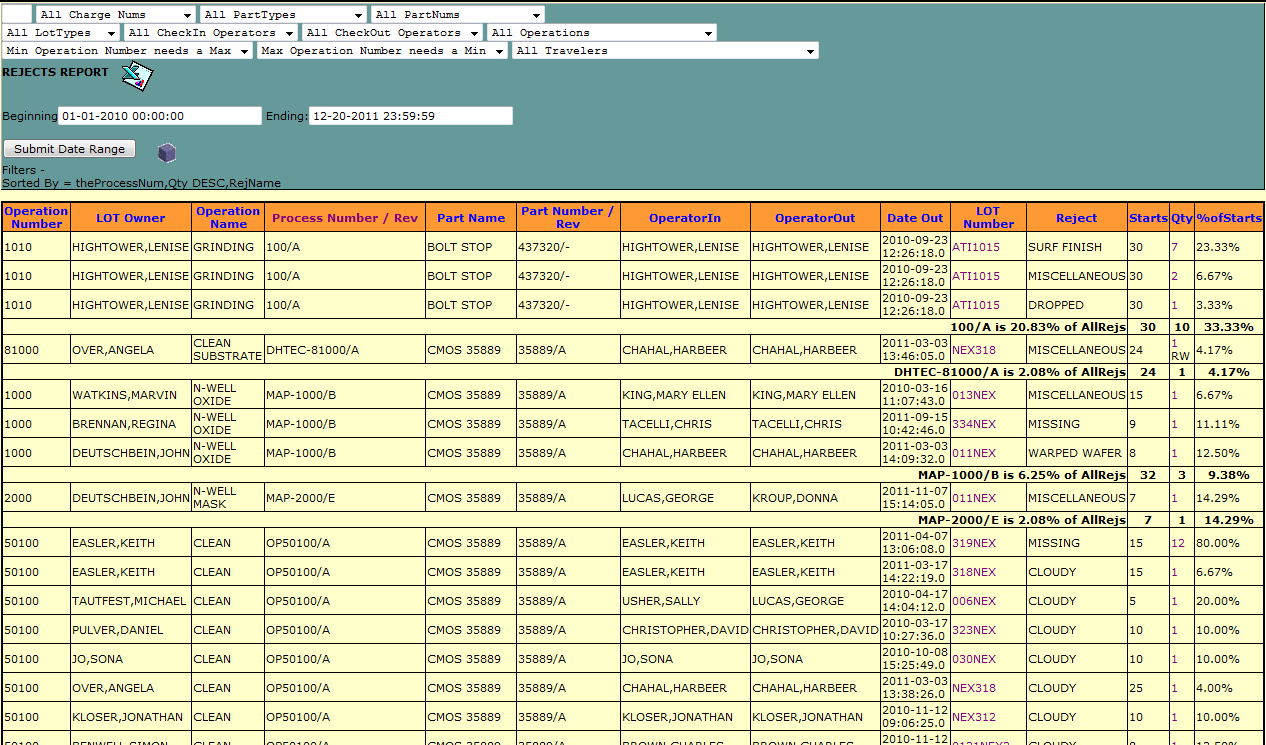

Work In Process WIP Capabilities

WIPtrac has extensive Work In Process tracking and reporting features showing WIP items like parts moved, good parts out, rejects, reworks, transferred to rework and much more. The reporting system for WIP data allows you to slice and dice your data in unlimited ways across unlimited numbers of parts and reports are all exportable to Excel spreadsheets with a single mouse click.

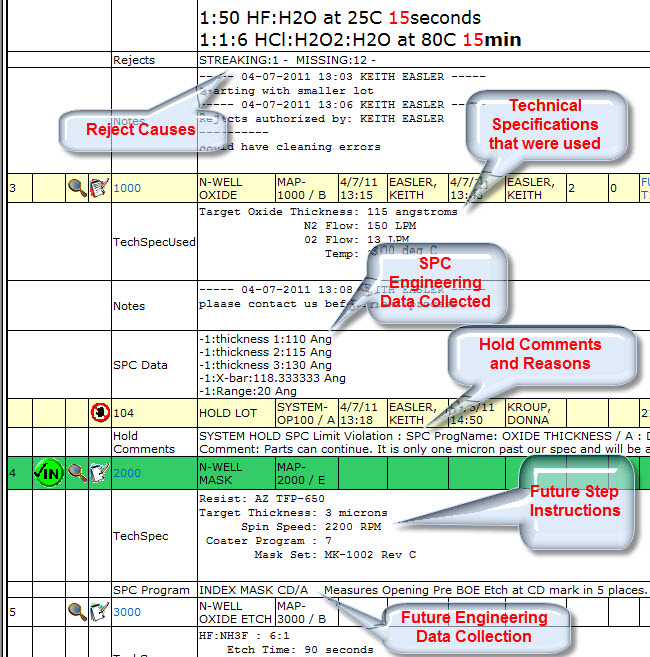

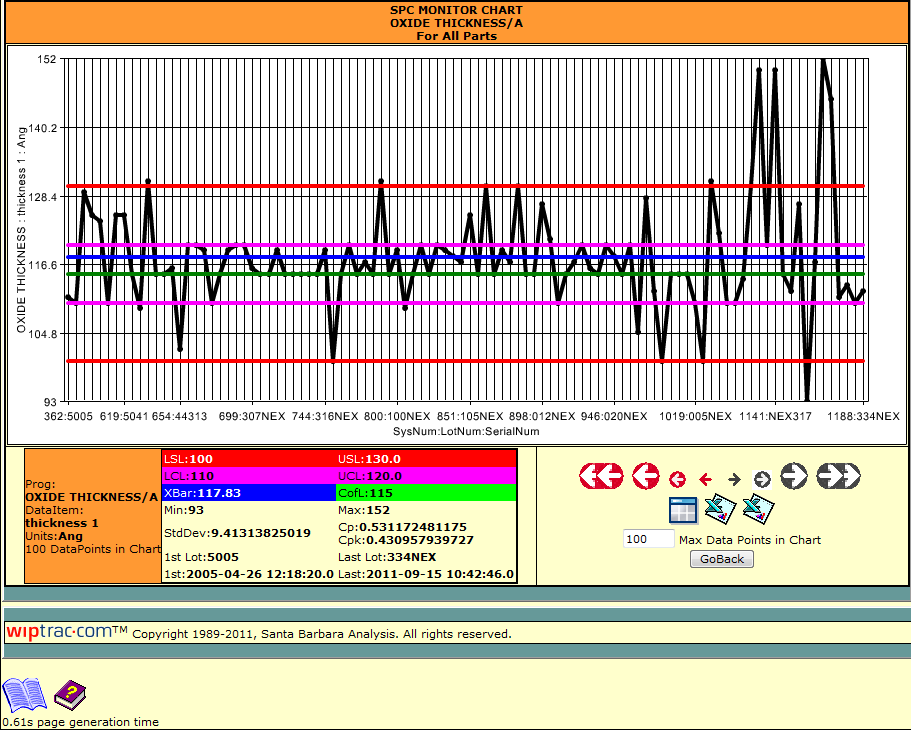

Statistical Process Control SPC, SQC and QMS Capabilities

Statistical Process Control (SPC), Statistical Quality Control (SQC) and Engineering Data Collection (EDC) becomes a valuable part of factory management as WIPtrac collects, analyzes, monitors, generates warnings, sends alert e-mails and text messages and shuts down lots, operations or equipment based on incoming SPC data. The paper blizzard associated with engineering data is over when you use WIPtrac to handle the information.

Electronic Quarantine Features

There are 5 levels of hold available within WIPtrac. They can be used for Material Review Boards (MRB) or Engineering Change Orders (ECO) or Process Engineering Holds (PEH) for operations review or for any other purpose you might wish the system to stop work.

- Put Lot on Hold

- Put Lot on Future Hold

- Put Part Number on Hold

- Put Operation on Hold

- Put Equipment on Hold

Lot Number Hold, Operation Hold and Equipment Hold can trigger automatically if SPC or engineering data goes out of control. When this happens, WIPtrac will send e-mail and text messages to the appropriate parties.

ERP-MRP-CRM & Other Systems Integration

Using Point and Click Integration techniques you can configure WIPtrac to write directly to your ERP and other SQL based systems. As WIPtrac Lots move through your factory the simple Update table scripts that you write will update databases outside of WIPtrac.

Operator Qualification Enforcement

Operators are assigned a qualification status for the different operations and processes in the factory and the operator will not be allow to check into operations that they are not qualified for.

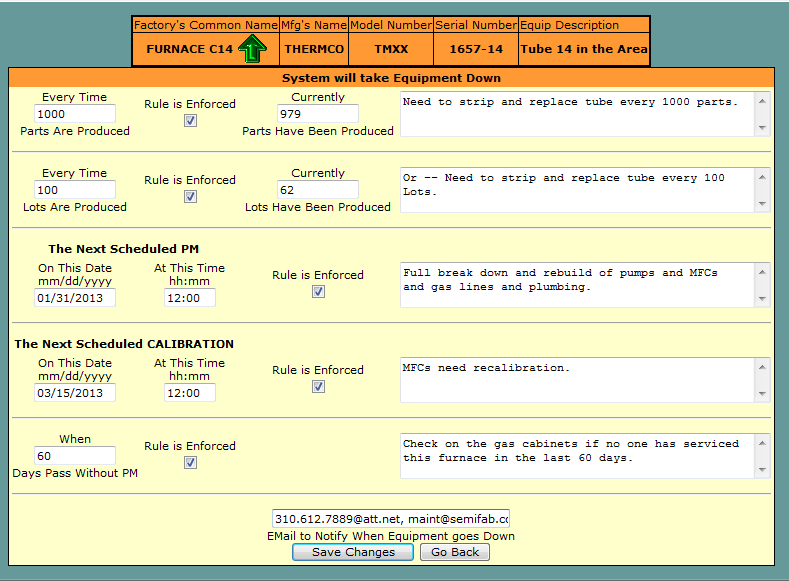

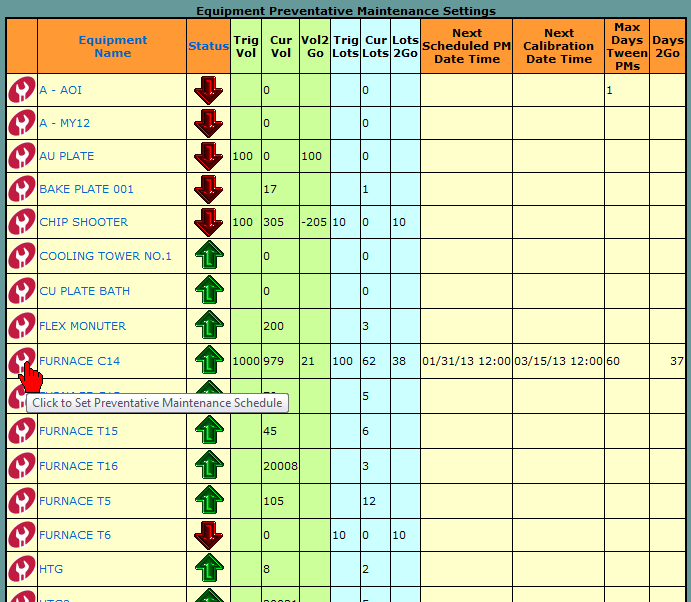

Equipment Tracking and Preventative Maintenance

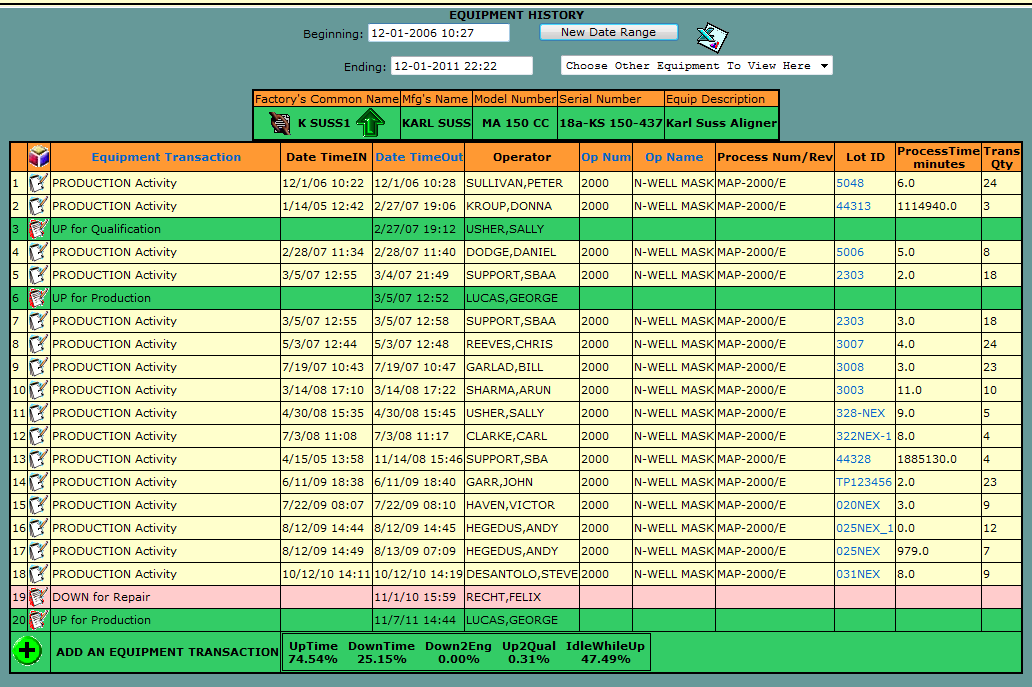

Equipment Tracking allows equipment and tools in your factory to be associated with multiple processes and operations. Likewise operations and processes can be associated with multiple pieces of equipment.

WIPtrac keeps a running total of what product and what quantities are produced by the equipment. Preventive maintenance triggers can be set for volume processed, runs initiated, time passed, SPC limits exceeded and others. If a tool goes down for maintenance either by triggering a limit or scheduled preventive maintenance, e-mail and text message notifications are sent to the appropriate parties.

ISO 9000 and ISO 9001 Configuration Management Features

ISO 9000 and ISO 9001 compliance is supported via complete configuration management system, modeled after similar paper systems. Operations, parts and part numbers, travelers and traveler numbers, etc. cannot be used by WIPtrac until they have been released. For example, once a new traveler has been reviewed and approved, configuration management personnel with the right security level and system password will release the traveler for use by factory floor operators.

Bar Code Enabled

WIPtrac was designed from the ground up to be bar code driven. WIPtrac generates bar code labels for you on any printer, using any desired format, readable by a myriad of different bar code wedges and readers.

Scheduling Capabilities

Using work content on travelers, WIPtrac predicts a ship date when a lot is kitted to the line and then constantly updates the predicted date while letting you know just how much ahead or behind the lot is running. Special on-line dispatch lists and reports give operators a quick look at what is in their queue at their workstation and from this list they can choose the hottest lots currently on the line to work on next. WIPtrac can be configured to e-mail daily alerts for manufacturing lots that are stalled and not moving.

It's all here and ready to use. If we can help in anyway please give us a call... or send us an e-mail.

SPC and Engineering Data

Engineering Data Collection (EDC) can occur every time parts are processed through an operation in the factory.

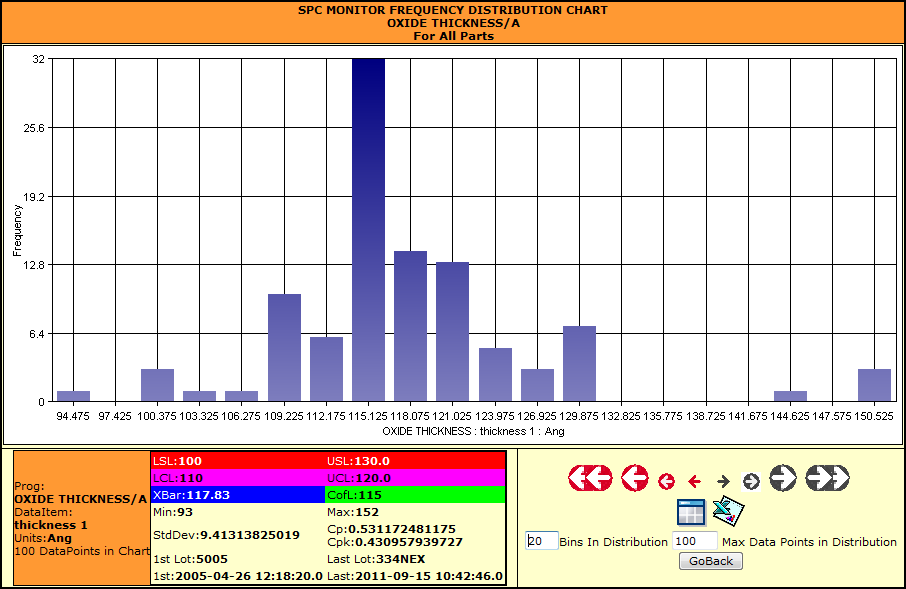

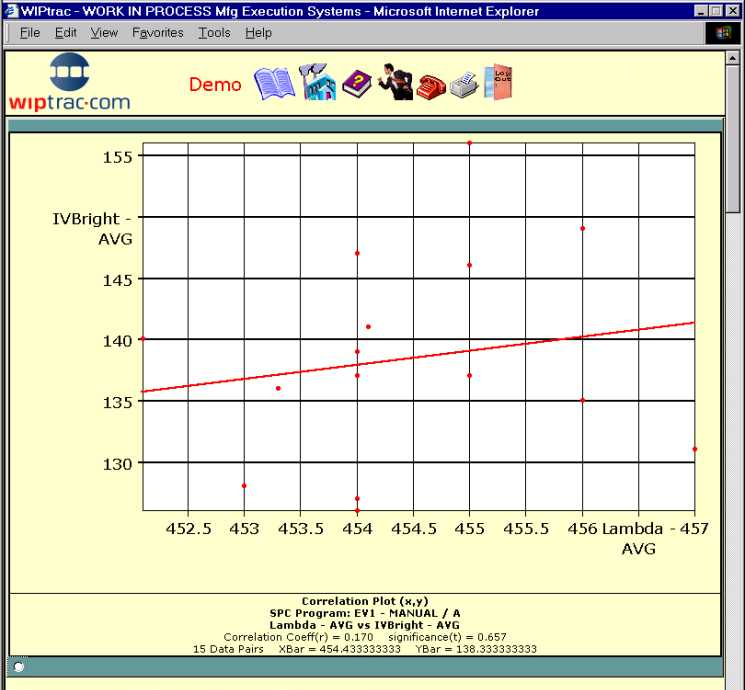

From the convenience of a computer terminal, your engineering and production control department can review up to the minute process data from factory operations. Track process data like:

- Control Limits

- Spec Limits

- Cp and Cpk

- Std Deviations

- Sigma

- Frequency Distributions

- Ranges

- Correlations

- User defined calculations

WIPtrac automatically keeps track of operations and sends alarms via e-mail and text messages when these process parameters go out of specification.

Statistical Process Control is the key to a quality product, shipped on time. When a process goes unmonitored, unmeasured and uncorrected, very large and unpredictable swings in both quality and quantity will occur.

Knowing where the product is in your factory, knowing when the product is going to ship and other critical information allows managers to make informed, competent decisions. However, SPC information about your process is just as important as Production Information.

WIPtrac supports and augments quality systems presently in place in high tech / high reliability manufacturing environments. WIPtrac delivers many features in support of ISO 9000 and ISO 9001 for plants looking to implement or upgrade a quality system.

- Enforces onfiguration management systems.

- Collects and analyzes SPC data automatically.

- Enforces manufacturing specifications.

- Enforces operator qualification status.

- Keeps manufacturing process, procedures, drawings and technical specifications on-line at all times.

- Makes quality auditing possible where it was previously a chore.

- Easily configured

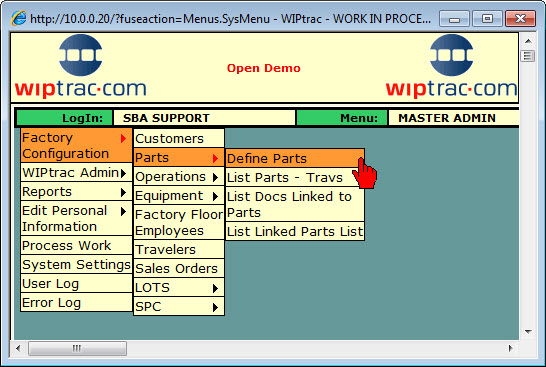

Configuration Management

WIPtrac is built from information supplied to it by the user. WIPtrac knows nothing about your factory until you build up a list of manufacturing operations that are performed by your shop floor employees. This list holds information like: charge number, process/operation number, revision level, default technical specs, and document and drawing numbers necessary for the operation.

As each operation is entered into WIPtrac, it must go through a release cycle similar to the release cycle used for paper document systems. The significance of this is that operations can only be released by your Configuration Management department with the release code for WIPtrac and the software will only allow for released operations to be included in routings or travelers. Like operations, routings and travelers must go through a release cycle before WIPtrac will allow them to be used on the factory floor. This system of release authorization enforces compliance to Configuration Management principles.

SPC Data Collection and Analysis

When a process goes unmonitored, unmeasured and uncorrected, very large and unpredictable swings in quality and quantity will occur.

SPC is a key element of WIPtrac and is integral to the way the system works. Engineering Data Collection and Analysis occurs every time parts are processed through an operation in the factory. From the convenience of a computer terminal, your engineering department can review real-time data from factory operations and dump data out to Excel spread sheets and statistics software packages.

Operations have data value control limits, range value control limits and spec limits that can be used to control your factory. As data is collected, it is compared against the three types of limits and depending upon which values are exceeded or violated, different actions can be triggered. The system can be configured to automatically put operations, lots and equipment on hold that violate the limits. WIPtrac uses the WESTERN ELECTRIC "RUN RULES" to determine if data is out of control. This refers to the data that exceeds limits as well as the 2 out of 3, 4 out of 5 and 8 in a row methods of detecting unstable processes.

Manufacturing Specifications Enforcement

Engineering Data Collection (EDC) occurs every time parts are processed through an operation in the factory. From the convenience of a computer terminal, your engineering and production control departments can review up to the minute process data from factory operations. WIPtrac automatically keeps track of operations and sends alarms by e-mail or text message when process parameters go out of specification.

Knowing where the product is in your factory, knowing when the product is going to ship and other such information is critical in helping managers make informed, competent decisions.

However, information about your process is just as important as production information. Process control is the key to a quality product, shipped on time. When a process goes unmonitored, unmeasured and uncorrected, very large and unpredictable swings in both quality and quantity will occur.

Integrated SPC is a benefit of running WIPtrac Manufacturing Execution Systems.

40108 Hwy 49 Ste C417

40108 Hwy 49 Ste C417

.png)